Using fungi to produce sustainable platform chemicals

Biotech startup Biophelion is working on extracting new valuable materials from industrial waste

Advertisement

The new startup wants to accelerate the transition to a circular economy in industry. Biotechnological processes are to be used to bring more sustainability to the material-intensive chemical industry, which has caused massive environmental problems in the past. The two founders, Lars Regestein and Till Tiso, have an unusual helper at their side: a yeast-like black fungus. The two engineers want to use it to convert mixtures of substances that were previously considered worthless by-products or even waste into usable compounds. To do this, they are taking advantage of the enormous variability in the fungus's metabolism. This enables the microorganism to convert carbon-containing mixtures of substances from industrial (waste) streams, such as those produced in large quantities in bioethanol production or during the manufacturing of sugar and paper, into new products. As a result, the carbon contained in these substances does not end up in the atmosphere as climate-damaging carbon dioxide, as was previously the case, but is returned to human use.

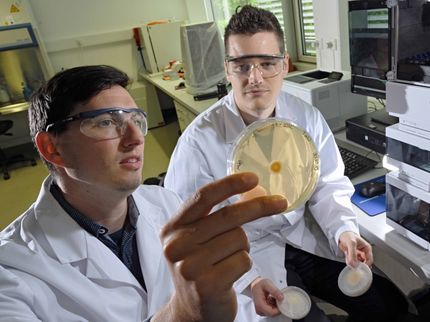

The two founders, Lars Regestein (left) and Till Tiso (right), on their way to the laboratories of the BioInstrumentation Center

© Tillmann Franzen

A fungus with potential

The black yeast produces three key compounds from these waste materials: a polyester that could be used in the future to make plastic for packaging, for example; the edible polymer pullulan, which is already used in food production today; and a novel surfactant whose properties and potential commercial applications are currently being investigated. “Biophelion is specifically developing applications that are not yet conceivable today – we are breaking new ground with pullulan and our surfactant molecule in particular,” says Till Tiso. One idea is to use pullulan as a material for 3D printing. The manufacturing process has experienced an enormous boom in recent years, which is associated with high material requirements. Pullulan could replace or at least supplement traditional plastics for 3D printing in the future. The two founders can even imagine producing 3D-printed bioreactors for the circular bioeconomy from pullulan in the future, which would allow their microorganism to produce their own culture vessel, so to speak.

Surfactants, on the other hand, are mass-produced and a main ingredient in laundry detergents and dishwashing liquids. This means they end up in wastewater and pollute the environment. Biologically produced and therefore easily degradable alternatives are an important contribution to reducing the ecological footprint.

Success with SPRIND

The impetus for the start-up came from the Federal Agency for Breakthrough Innovations SPRIND. The “Circular Biomanufacturing Challenge” organized by SPRIND is specifically designed to promote the establishment of new high-tech companies in the life sciences. It is a risky undertaking, but one that also offers great opportunities. Even just one of the funded projects can recoup the entire investment in such a competition if it proves successful and secures a competitive advantage for Germany as a business location. Biophelion was founded as a joint spin-off of Leibniz-HKI and RWTH Aachen University during the second of a maximum of three funding phases. “SPRIND has given us momentum – in terms of content, finance, and strategy,” emphasizes Lars Regestein, who will serve as CEO in the future. Till Tiso will take on the role of CTO while continuing to work in academic research. The start-up will move into offices in the BioInstrumentezentrum on the Beutenberg Campus in Jena, just a stone's throw away from Leibniz-HKI. Close cooperation with the institute will continue in the future in order to further optimize the bioprocesses for manufacturing the new products. As a technology transfer partner of Leibniz-HKI, Ascenion GmbH has accompanied the project from the outset and was involved in the spin-off process.

"Leibniz-HKI is delighted to be able to continue accompanying and supporting the two founders as a participating institution in the future. We greatly appreciate the excellent scientific expertise of Lars Regestein and Till Tiso, as well as their courage in founding their own company. We now wish the newly appointed managing directors every success with Biophelion," says Axel Brakhage, Director of Leibniz-HKI.

The founders

Lars Regestein studied mechanical engineering and process engineering in Dresden. In 2007, he began his doctorate under the scientific supervision of Prof. Jochen Büchs at RWTH Aachen University in the field of bioprocess engineering, which he successfully completed in 2012. He then became senior engineer at the same department and worked on viscous systems, mixed culture processes, and integrated downstream processes. He interrupted his time in Aachen in 2014/15 for a research stay as adjunct professor at Western University in London, Ontario, Canada. Since 2017, Lars Regestein has been conducting research at the Leibniz-HKI in Jena. His team develops and scales processes from microliter to cubic meter scale, covering the entire process from raw material to pure product.

Till Tiso studied bioengineering at TU Dortmund University. In 2011, he moved to the Institute of Applied Microbiology at RWTH Aachen University, where he completed his doctorate in 2016. He then took over the management of his own research group and habilitated in 2024 with work on the role of microbiology in the circular bioeconomy. Research stays took him to Imperial College London and CSIC in Madrid, among other places. Since 2025, he has been Professor of Systems Biotechnology at Bielefeld University. His scientific focus is on the development of sustainable biotechnological processes for industrial implementation.

Other news from the department science

Most read news

More news from our other portals

Something is happening in the life science industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.