SemBioSys achieves major insulin milestone

Canadian Biotechnology Company achieves commercially viable level of insulin in safflower

Advertisement

SemBioSys Genetics Inc. has achieved its commercial target levels of human insulin (insulin) accumulation in safflower with 1.2 percent of total seed protein. The results from the Company's commercial plant system exceeded its target of one percent accumulation and confirm the potential of plant-produced insulin to fundamentally transform the economics and scale of insulin production.

"These results demonstrate that we have produced an authentic insulin molecule in safflower at commercially viable levels. Achieving our goal of one percent insulin accumulation in safflower confirms that SemBioSys has the potential to dramatically impact the economics of insulin manufacturing," said Andrew Baum, President and CEO of SemBioSys Genetics Inc. "At these levels we can produce over one kilogram of insulin per acre of safflower production, which is enough to supply 2,500 patients for one year of treatment. We believe that we could meet the world's total projected insulin demand in 2010 with less than 16,000 acres of crop production. Our plan is to continue to scale-up production for sufficient material to initiate clinical trials and file an Investigational New Drug (IND) application in the second half of 2007."

SemBioSys intends to continue its preclinical program with safflower-derived insulin and assemble the components of its IND application including toxicology, immunology profiles and demonstration of efficacy in animal models. The Company expects to be in a position to submit an IND to the U.S. Food and Drug Administration in the second half of 2007 in preparation for a clinical trial in late 2007 or early 2008.

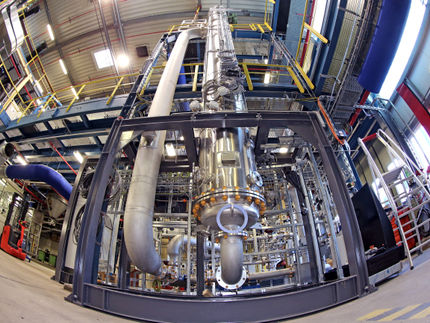

Existing commercial insulin production methods typically rely on yeast (Saccharomyces cerevisiae) or bacteria (E. coli) genetically engineered to produce synthetic human insulin. These organisms are grown in large, capital-intensive steel bioreactors and the insulin is then extracted and purified for final formulation.

Through its proprietary technology, SemBioSys is able to accumulate recombinant proteins, like insulin, in safflower. As the plant grows and the seed develops, the insulin protein is produced in the seed. Safflower production is based on conventional farming practices that have been adapted to ensure product integrity and confinement. The harvested seed is then processed using SemBioSys' proprietary extraction process. Conventional enzymatic or chemical cleavage techniques and downstream processing methods are employed to produce purified insulin.