Pharmaceutical Production with Reduced Waste

Platform technology for producing cephalosporin antibiotics

Advertisement

antibiotics save countless human lives – modern medicine without them is unimaginable. The largest proportion by volume of industrially produced antibiotics today are cephalosporins, structural variants of the first antibiotic, penicillin. Unfortunately, their production generates a considerable amount of waste products, some of which are questionable. In the European Journal of Organic Chemistry, scientists have now demonstrated that a newly developed, more ecological synthetic route is suitable for the production of a wide variety of cephalosporin antibiotics.

Penicillin is among the ß-lactam antibiotics, a class of substances whose common component is a lactam, a four-membered ring consisting of one nitrogen atom and three carbon atoms, one of which is attached to an oxygen atom through a double bond. Cephalosporins, the second most significant subclass of the ß-lactam antibiotics, contain a bicyclic system made of the ß-lactam ring and a six-membered ring made of sulfur, nitrogen, and carbon atoms. The various therapeutically useful drugs in this class differ in their side chains, which can be attached at various places on the basic framework.

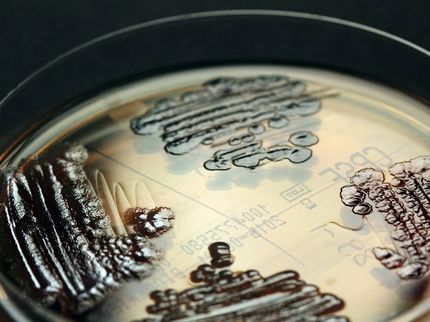

The production of cephalosporin antibiotics is a semi-synthetic process. A fermentation first yields cephalosporin C, which is then enzymatically split to form 7-aminocephalosporanic acid (7-ACA). Different drugs are then produced from 7-ACA through chemical syntheses. Production of third-generation cephalosporin antibiotics involves attachment of an amino group (a nitrogen-containing group) of the lactam ring to a building block based on (Z)-(2-aminothiazol-4-yl)methoxyiminoacetic acid. Both the production of this reactant and the binding reaction are ecologically unfavorable because they result in large amounts of partially dubious waste products. These are formed because a variety of reagents are needed for activation, for protection of groups that are not supposed to react, and for the coupling itself, depending on which drug is being produced.

A team headed by Harald Gröger (Bielefeld University, Germany) recently cooperated with the Provadis School of International Management and Technology and the generic drugs manufacturer Sandoz GmbH (Kundl, Austria) to develop an interesting alternative for this type of amidation reaction, and used it to make cefotaxime. The key to their success was the use of tosyl chloride, an established, inexpensive coupling reagent, in combination with methanol as an unproblematic solvent. The only side product is toluenesulfonyl acid, which is more attractive from the toxicological point of view since it requires neither protective groups nor activators that could form waste products. “This is a very favorable process with regard to atom economics,” says Gröger. Atom economics considers the percentage of atoms in the starting materials that are actually transferred to the products in a chemical reaction.

Scientists at Bielefeld University and Sandoz GmbH have now been able to demonstrate that their amidation method is generally suitable for the production of third-generation cephalosporin antibiotics. In a research project funded by the Deutsche Bundesstiftung Umwelt (DBU, German Foundation for the Environment), they successfully synthesized three further cephalosporin antibiotics: cefpodoxime, cefpodoxime proxetil, and a precursor of ceftazidime. Despite non-optimized reaction conditions, their yields of 82-95 % are very high. “It is particularly noteworthy that many different functional groups at diverse positions on the 7-ACA-based starting molecules are tolerated,” says Gröger. “Our ecologically and economically advantageous synthetic route offers the prospect of broad application in the industrial production of cephalosporin antibiotics.”