New method for rapidly producing protein-polymers

Advertisement

Duke University bioengineers have developed a new method for rapidly producing an almost unlimited variety of man-made DNA sequences.

These novel sequences of recombinant DNA are used to produce repetitive proteins to create new types of drugs and bioengineered tissues. Current methods for producing these DNA sequences are slow or not robust, the researchers said, which has hindered the development of these increasingly important new classes of protein-based polymers.

Researchers have already demonstrated that when a large protective macromolecule (polymer) is attached to a protein, it greatly improves effectiveness and allows the protein to remain active in the bloodstream longer. There are many protein-polymer based medications in use today, such as human growth hormones, drugs to stimulate blood cell formation in cancer patients and anti-viral agents.

"This new technique should be very useful in making a practically unlimited number of these protein building blocks," said Ashutosh Chilkoti, Theo Pilkington Professor of Biomedical Engineering at Duke's Pratt School of Engineering. The results of the Duke team's experiment were published online in the journal Nature Materials . Graduate students Miriam Amiram and Felipe García Quiroz, working in Chilkoti's lab, were co-first authors of this paper.

"Depending on how complicated you want the polymer sequence to be, there are an infinite number of combinations you could make," Chilkoti said. "We haven't even begun to look at all the sequences that can be made or the unique properties they might have."

The researchers call the new process overlap-extension rolling circle amplification, and it is a modification of existing technologies. Because of this, they said that other laboratories would not need major investments in new equipment or materials.

"A very popular method for making tandem copies of DNA sequences involves inserting them iteratively into a bacterial plasmid," Amiram said. "After the vector has grown in size, the copies of the sequence are cut out using enzymes and the process is repeated to generate a larger polymer. It is a very time-consuming process.

"With this new method, you don't get just one product, but many," she said. "This should help us to make large libraries of proteins, which we can use to rapidly screen new combinations. This powerful strategy generates libraries of repetitive genes over a wide range of molecular weights in a 'one-pot' parallel format."

Chilkoti compared it to sausage-making. Instead of stuffing the casings one-by-one individually, the new tool can rapidly stuff and stitch together long strings of sausages.

"This could help remove one of the biggest stumbling blocks we face in producing these drugs," Chilkoti said. "You can't make the proteins without genes, which act as the software directing the protein's production. Instead of building each sequence individually, as is done now, we can literally make hundreds, each with subtle differences."

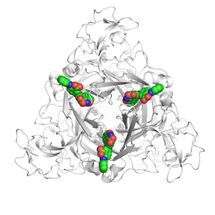

The researchers used the system to synthesize genes found in two classes of protein-polymers. In the first, they produced protein-polymer combinations for elastin, a ubiquitous protein found in connective tissue. The researchers term them "smart" protein-polymers because they can be controlled by heat.

In the second set of experiments, they rapidly synthesized novel glucagon-like peptide-1 (GLP-1) analogs to show variable pharmokinetic properties. GLP-1 is a hormone that acts to release insulin in the body.