P-14

Two instruments in one compact solution for demanding samples

up to 24,000 rpm for fine grinding

active air cooling with separate fan and switchable vacuum

durable high-performance motor with low-wear ceramic groove ball bearing

New

New

New

New

New

New

Impact and cutting in a single unique combination

FRITSCH COMBINES IMPACT AND CUTTING ACTION IN A SINGLE DEVICE FOR THE FIRST TIME

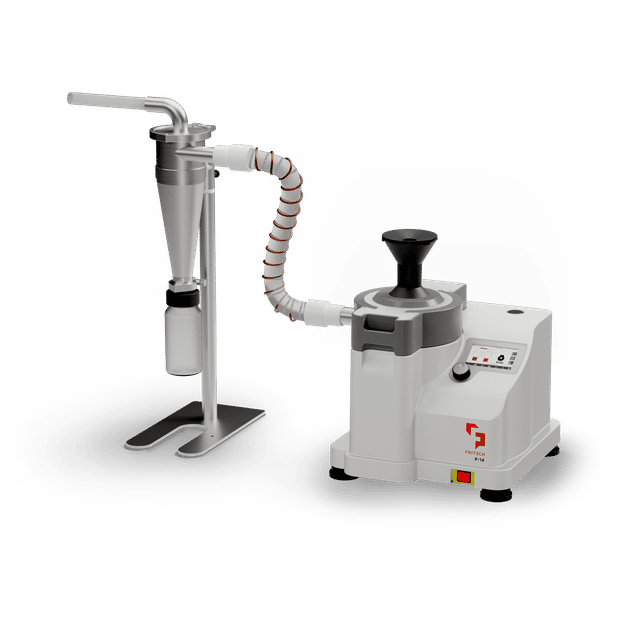

With the P-14, FRITSCH has developed an all-in-one solution for impact, shearing, and cutting size reduction. It is currently the only rotor mill based on the impact principle that can be converted into a cutting mill with just a few simple steps. This makes FRITSCH the first to offer two sample preparation instruments in one compact solution—delivering outstanding performance and efficiency in both applications. This is particularly attractive for companies that process a wide range of samples and can therefore save on equipment. The efficient rotor mill is now available on the market.

At a rotational speed of 24,000 revolutions per minute, the P-14 achieves a throughput of more than 15 liters per hour. This allows the laboratory device to process a wide variety of materials particularly quickly. In combination with a FRITSCH cyclone, users can also grind heat-sensitive, electrostatically charged, or especially lightweight materials. A separate cooling fan, which operates independently of the motor and cools before, during, and after grinding, enables active air cooling. Thanks to this feature, even temperature-sensitive substances such as essential oils can be preserved largely without loss during series grinding and without long cooling times. This is supported by a sensor located in close proximity to the rotor that continuously measures the system temperature. The corresponding data can be viewed graphically on the display at any time. The current system load is also shown there. This gives users full control over the entire grinding process and allows entire sample series to be processed under consistently identical conditions.

The P-14 can be easily adapted to a wide range of requirements thanks to grinding attachments that can be exchanged with just a few simple steps. Using the impact rotor, the rotor mill effortlessly comminutes soft to medium-hard, brittle materials ranging from limestone to ground grain. The cutting set, on the other hand, is suitable for the pre- and fine grinding of soft to tough or fibrous materials—from textiles and synthetic resins to polyester. For highly sensitive materials such as powder coatings, special plastics, or residual-moist samples, an additional impact strip is available. A patented detection system for the individual grinding set components and the associated menu guidance prevent operating errors and ensure safe, clearly guided, and smooth operation—even when handling different sample requirements.

1

Automatic Sample Feeding with the FRITSCH Vibratory Feeder Chute

2

Keep an eye on temperature and system load

3

Two functions in one mill

Request information about P-14 now

Rotor mills: P-14

Two instruments in one compact solution for demanding samples

Product classification P-14

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more rotor mills and related products

Find P-14 and related products in the theme worlds

Topic World Sustainability in the laboratory

The main topic of sustainability in the laboratory highlights innovative approaches and technologies that reduce the ecological footprint in laboratories. These include energy-efficient equipment, resource-saving consumables, green chemistry, recycling initiatives and sustainable laboratory management solutions.

Topic World Sustainability in the laboratory

The main topic of sustainability in the laboratory highlights innovative approaches and technologies that reduce the ecological footprint in laboratories. These include energy-efficient equipment, resource-saving consumables, green chemistry, recycling initiatives and sustainable laboratory management solutions.