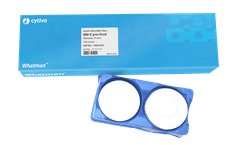

Hydrosart® Microfilter

Maximum flux with Hydrosart® membranes: Stable, hydrophilic and non-protein binding

Hydrosart® high performance membrane is a stabilized cellulose based membrane optimized for biopharmaceutical process applications. It is stable across a broad pH range and extremely hydrophilic, making it non-protein binding and virtually non-fouling.

- Ultra-low protein adsorption

- Easy cleaning

- Higher yields

- Long product life

- Retains its performance even with repeated re-use without fouling or loss of retention

Hydrosart® Microfiltration Cassettes are available in the following molecular weight cut offs: 0.2 μm and 0.45 μm

They can be used to remove the following from liquids:

- Mammalian cells, CHO, BHK

- Bacteria, E coli, Pasteurella, C. diphtheria

- Yeasts

- Cell lysates

Request information about Hydrosart® Microfilter now

Microfilters: Hydrosart® Microfilter

Maximum flux with Hydrosart® membranes: Stable, hydrophilic and non-protein binding

Product classification Hydrosart® Microfilter

Product categories

Applications

Manufacturers of similar products

Find more microfilters and related products

Find Hydrosart® Microfilter and related products in the theme worlds

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.