Victorian Research Facility Building World's Largest Parallel Protein Production Facility With GE Healthcare

Advertisement

The world's largest parallel protein purification workstation is to be housed at Monash University, improving Australian scientists' abilities to study the molecular structure and function of proteins. The ÄKTAxpress - from GE Healthcare - allows up to 48 proteins to be produced simultaneously giving Australian scientists the materials they need to conduct life-saving protein-based research in Australia.

Victorian Bioinformatics Consortium Scientific Director and Monash University researcher, Dr James Whisstock, said protein research currently focused on understanding how proteins function or dysfunction, and in particular understanding the atomic structure of these molecules.

"If we understand the molecular shape of a protein, we can begin to understand how it works," said Dr Whisstock. "Heart disease, cancers, osteoporosis and immune deficiencies are just some examples of illnesses that manifest through the actions of proteins, so knowing how proteins function not only gives us a better understanding of these illnesses, but also points the way to effective therapies. Currently our ability to study the molecular structure and function of proteins is constrained by the rate at which we can produce proteins for analysis."

The workstation is closely linked to Victoria's $180 million Australian Synchrotron facility due to open in 2007. The ÄKTAxpress is a modular system developed for the high-throughput purification of protein samples, automating the multi-step purification process to yield highly purified protein. Monash has invested in a 12-module ÄKTAxpress system, the largest configuration of its kind anywhere in the world.

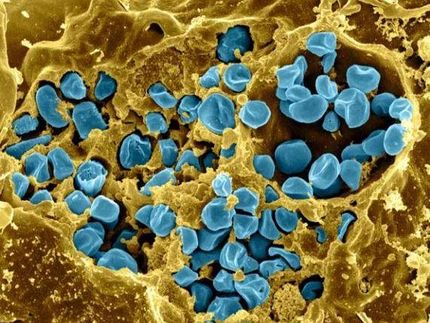

"At present one scientist basically produces one protein at a time," explained Dr Whisstock. "The process involves growing bacteria in the lab, disrupting the cells, washing the samples and finally extracting and purifying the proteins, and can take up to a week to complete. Owing to equipment and personnel constraints we often have to wait for one production run to end before we can start another one. That's where the ÄKTAxpress comes in: it allows us to produce 48 different proteins in parallel, in genuine production scale. A typical scientist would be hard pushed to produce large scale quantities of 48 different proteins in a year, let alone in the eight hours it takes for the Äktaxpress to do its work."