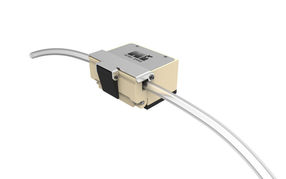

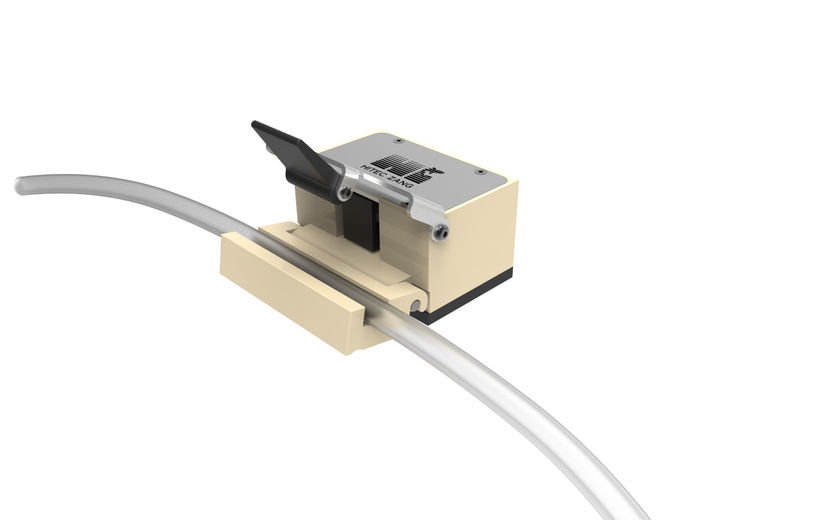

Hose pressure transducer

Contactless hose pressure measurement – this is how it’s done

Convenient - Easy to mount directly on the hose’s outside

Non-invasive - Perfect for sterile applications, no contact with the medium in the hose

Versatile - Suitable for hose and tube diameters from 4.8 to 19.1 mm

Convenient filter monitoring and clogging detection from the outside while sterility is maintained

Pressure sensors or pressure transducers are essential to detect clogging of filters or pumps early enough to avoid follow-up malfunction. A particular challenge is measuring the pressure in sterile applications. Due to the non-invasive measurement by the sensor on the outside of the hose, there is no contact with the medium, which also extends the sensor’s service life. Annoying dead spaces are avoided, allowing you to focus on your process.

The sensor is perfectly suited for use under sterile conditions.

You can easily mount the pressure sensor to hoses and tubes with a diameter of between 4.8 and 19.1 mm, but we are happy to provide special sizes on request. Start straight away after calibration.

Hose pressure measurement has never been as easy as this – what are you waiting for?

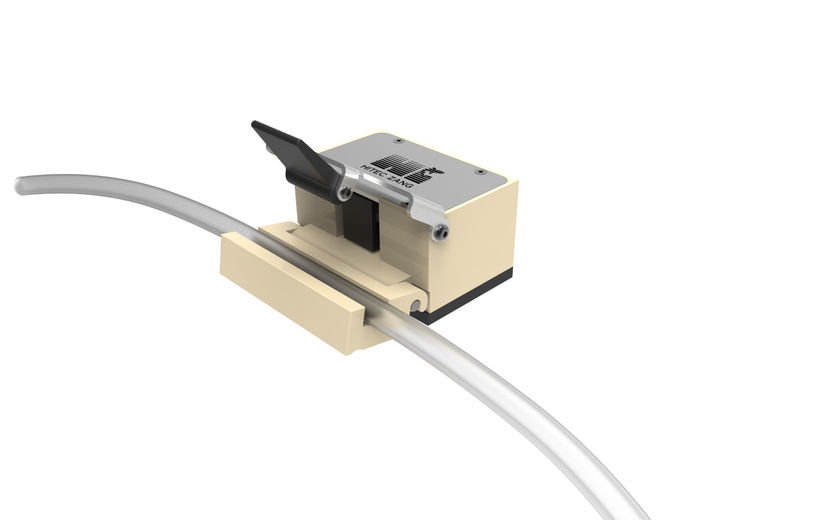

1

Insert hose, close, and you’re done: the easy way to mount this hose pressure sensor saves you time

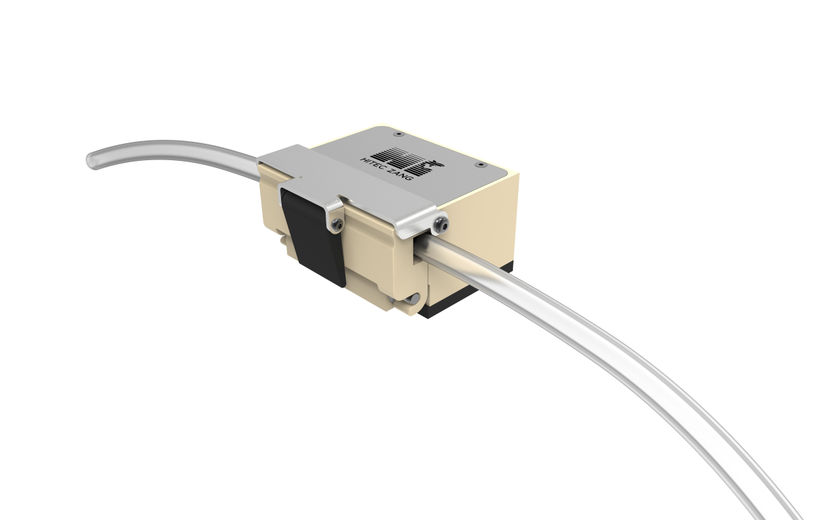

2

Non-invasive pressure measurement from the outside to maintain sterility

Request information about Hose pressure transducer now

Hose pressure sensors: Hose pressure transducer

Contactless hose pressure measurement – this is how it’s done

Product classification Hose pressure transducer

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more hose pressure sensors and related products

Find Hose pressure transducer and related products in the theme worlds

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.