New international partnership promises great potential for next-generation biopharmaceuticals

New virus-free insect cell line

Advertisement

There are a multitude of challenges associated with the production of next-generation biopharmaceuticals and vaccines. The Austrian Centre of Industrial Biotechnology and the BOKU - University of Natural Resources and Life Sciences, Vienna together with the Boyce Thompson Institute (BTI) Ithaca, NY are developing a new production platform that promises faster, more economic and safer production of modern pharmaceuticals - from gene therapies for neurodegenerative disorders such as Parkinson's or Alzheimer's, to cancer therapy and modern preventive vaccines against influenza, HIV, dengue or zika virus.

Modern biopharmaceuticals are often based on the mass production of designer proteins, such as virus-like particles (VLP) for gene therapy or for the development of vaccines, to support the organism in producing antibodies against various pathogens. Imagine the immune system as a memory match player busily identifying the surfaces of any virus that appears and developing resistances as soon as it gets into contact with the virus. VLP make use of this principle: they imitate the surface of the virus and feign an infection without damaging the body, because the dangerous genetic material inside the virus envelope that is responsible for infection, has been removed.

Since the surface proteins of VLP can be tailored to various applications, this technology is becoming ever more interesting for industry. However, the production of this specialized biomolecules calls for improved and above all, more robust production procedures.

Conventional production procedures have significant disadvantages

For fifty years, vaccines have been produced by means of seed viruses. These are living pathogens that multiply in cells from chicken eggs. Seed viruses are used, for example, to produce approved influenza vaccines. The rule of thumb "one vaccine dose per egg" means that the number of vaccines is limited to 150 to 200 million available eggs worldwide. Formerly used alternative platforms - such as vaccine production in cultured cell lines of eukaryotic organisms such as yeasts and insects - have the disadvantage of instability.

New virus-free insect cell line

In a joint project, the Austrian Centre of Industrial Biotechnology (acib) and the Boyce Thompson Institute (BTI) at Cornell University are investigating a platform technology for the optimised production of diverse proteins. "This has become possible thanks to a cell line developed by BTI that for the first time is free of a certain type of insect virus that has been an issue for these cells in the past", explains acib researcher and project manager Reingard Grabherr.

The process is currently being tested on pilot-plant-scale by acib. Using a sophisticated fermentation process, the genetically optimised insect cell line is stimulated to grow and produce protein in a bioreactor, before the scientists introduce the genetic information for the generation of designer proteins, which are purified from the insect cells after several days of production.

"Through cooperation with acib, BTI researchers are able to observe the new cell lines under conditions that normally prevail in commercial production. Testing the new technology in these conditions is novel for the university environment", said Paul Debbie, Director of technology transfer and licensing at BTI, who is pleased about this opportunity. Remarking on the value of collaboration for scaling up, Debbie said, "acib's capabilities are far beyond anything that we have here at BTI where we are mainly working at laboratory scale."

Major potential for biopharmaceutical industry

In a next step, researchers aim to prepare the pilot-production platform for industrial application, but to do so they must first carefully observe how the scaled-up process has affected the cell lines at a genetic level. "To achieve even higher process reliability and prevent losses, we carry out transcriptomics analyses and check how the 15,000 different genes of the cell behave", Wolfgang Ernst, researcher at acib, explains.

"As a new platform technology, the process entails great potential for the pharmaceutical industry", Alois Jungbauer explains. He is area leader at acib and researcher at the BOKU and has already established contact to interested international companies.

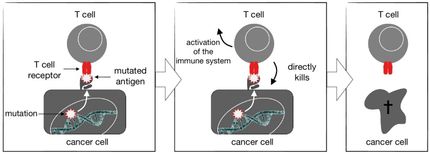

A wide range of next-generation biopharmaceuticals could be produced with the new technology in a few years and in a much faster, simpler and safer manner. Improved production of VLPs and other designer proteins will open the doors to a promising future of gene therapies for neurodegenerative disorders including Parkinson's or Alzheimer's, cancer therapy, and long-awaited preventive vaccines.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Gene therapy

Genetic diseases once considered untreatable are now at the center of innovative therapeutic approaches. Research and development of gene therapies in biotech and pharma aim to directly correct or replace defective or missing genes to combat disease at the molecular level. This revolutionary approach promises not only to treat symptoms, but to eliminate the cause of the disease itself.

Topic world Gene therapy

Genetic diseases once considered untreatable are now at the center of innovative therapeutic approaches. Research and development of gene therapies in biotech and pharma aim to directly correct or replace defective or missing genes to combat disease at the molecular level. This revolutionary approach promises not only to treat symptoms, but to eliminate the cause of the disease itself.