Sartorius

TakeOne®

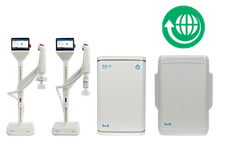

Aseptic sampling for all process requirements with TakeOne

TakeOne® sampling solutions were designed to meet the sampling requirements of today’s varied manufacturing approaches. They can be used to obtain samples from stainless steel reactors and vessels or single-use systems and assemblies, providing cost-effective and technically robust solutions for all microbiological and routine process monitoring assays. An array of bags, bottles and tubes are designed to preserve the aseptic integrity of the source from which the sample is taken.

Aseptic sampling is a principal component of an effective microbial control program. Samples collected with TakeOne® solutions are used to measure critical purity attributes, such as bioburden and endotoxin levels, as well as important process parameters, such as metabolites, nutrients, osmolality, pH and more. TakeOne® aseptic sampling solutions have been designed to integrate seamlessly with stainless steel or single-use processes. Our family of collection containers connect directly to single-use assemblies and systems via aseptic connectors or weldable TPE tubing, such as Tuflux® TPE and are suitable for everything from traditional biopharmaceutical sampling to advanced cell and gene therapies for regenerative medicines.

Plan for Adaptability with TakeOne® Flex. An ideal solution that allows you to react quickly on demand.

Our modular sampling solutions ease handling of complex process equipment and allow for variability with point-of-use connections. This provides the highest degree of flexibility and adaptability for sampling and small-volume fluid handling.

Product classification TakeOne®

Product categories

Applications

Manufacturers of similar products

Advertisement

Find more sampling systems and related products

Find TakeOne® and related products in the theme worlds

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.

Topic world biopharmaceutical manufacturing

Biopharmaceutical production plays a crucial role in the development and manufacture of biologics, which are essential for the treatment of various serious diseases. Various key technologies and processes of the modern biopharmaceutical industry are used, such as cell cultures, fermentation processes and the purification of biological substances, which are necessary for the production of vaccines, monoclonal antibodies and other biological drugs.